Our Technology

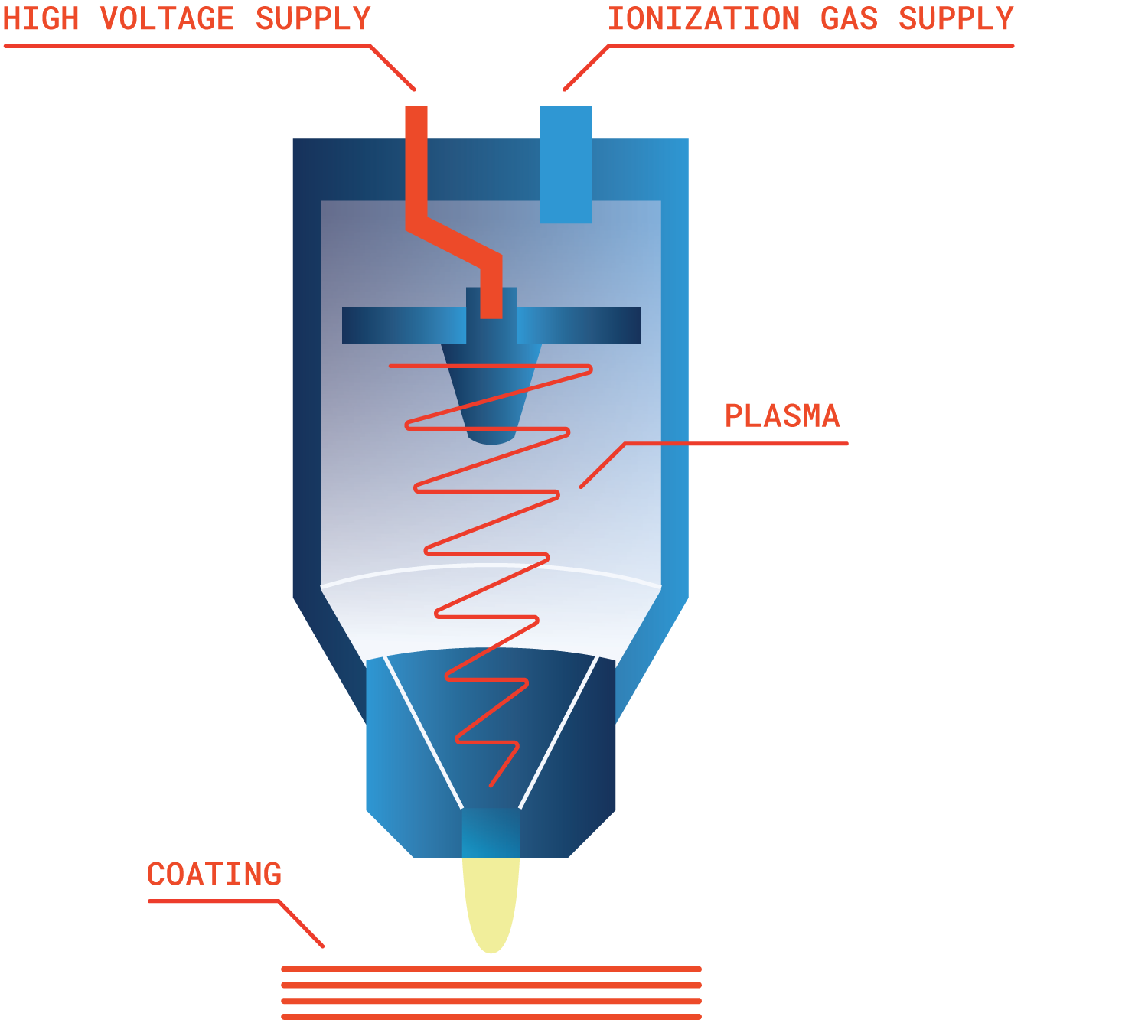

Our cold-plasma based 3D printing technique fundamentally changes the way battery cells are manufactured, enabling limitless possibilities for the shape and configuration of battery cells.

Intecells is redefining battery manufacturing from the ground up.

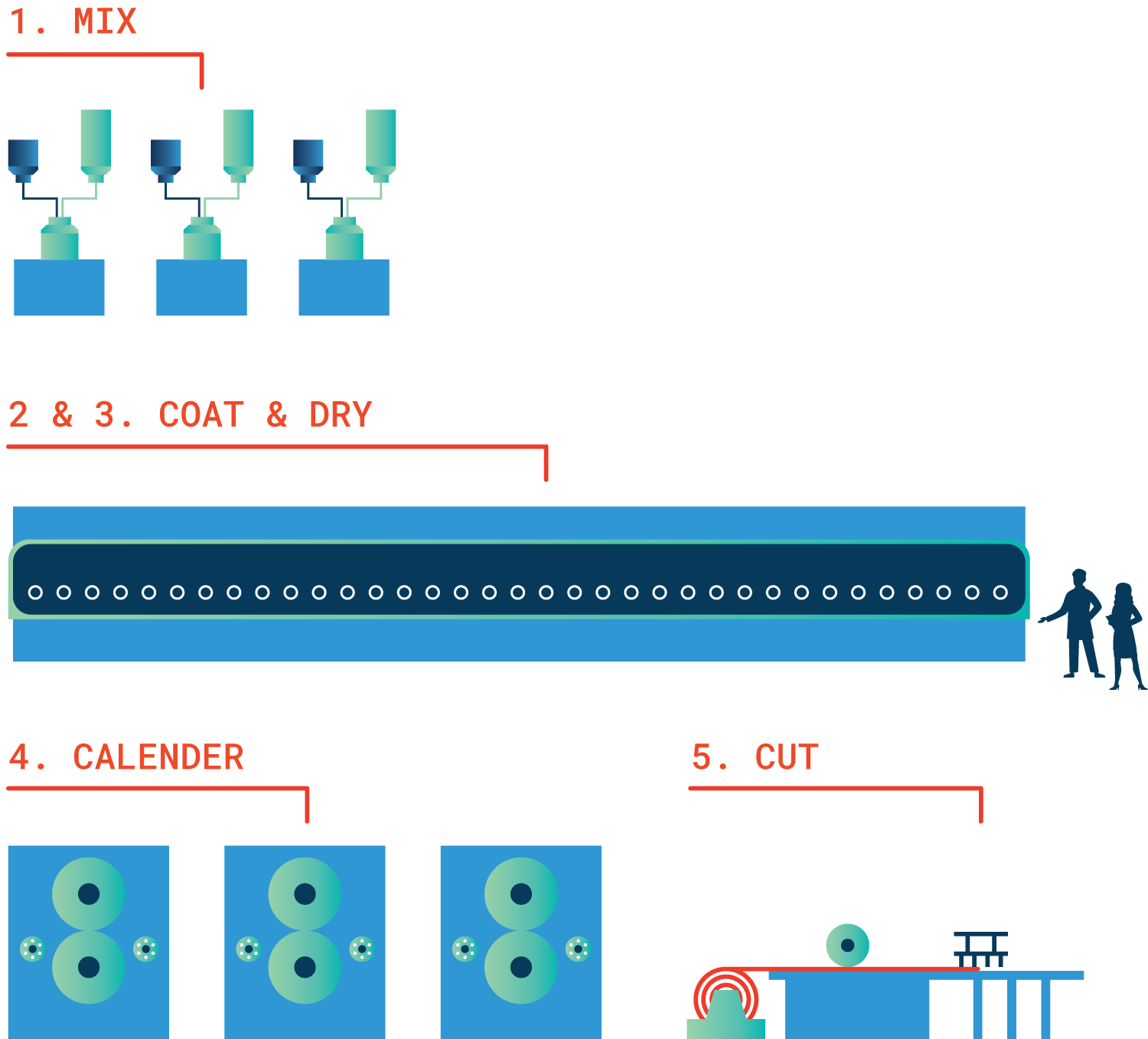

The Battery Industry Today

Currently, lithium-ion battery manufacturing entails a multistep slurry-casting process that requires high amounts of capital and energy but is only capable of producing flat electrodes with limited energy density.

The Innovation of Intecells

Intecells uses cold plasma powder coating (CPC) processes to create batteries with 3D topologies and exceptional performance suitable for any application.

Our technology benefits the entire battery value chain.

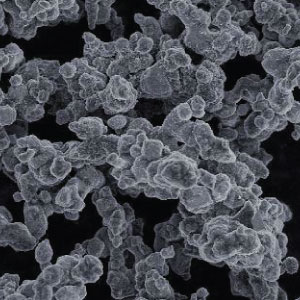

Materials

Cost advantages through strategic partnerships.

Electrodes

Electrodes for any chemistry, at any scale.

Battery/Cell

You design it,

we build it.

Pack

“Powder to pack” technology with unlimited possibilities.

The Intecells Advantage

Safety & Cycle Life

• 10x improvement in electrode

coating adhesion

• Improved separator stability

• Improved cycle life due to robust

coating process and cell design

Power & Energy Density

• Over 2x Energy and Power Density of Battery Cell

Cost

• 93% Manufacturing Cost Reduction

• Over 40% Battery Cost Reduction

Size & Shape

• Limitless Battery Cell Shape & Configuration

Footprint & Energy Usage

• 50x Less Electricity Consumption

• 60x Lower Manufacturing Footprint

Environmental Impact

• 50% Lower Carbon Emissions

• No Toxic Solvents

*Compared to battery cells produced by the current roll-to-roll wet transfer coating process.